INDIVIDUAL

PRODUCT

FEATURES

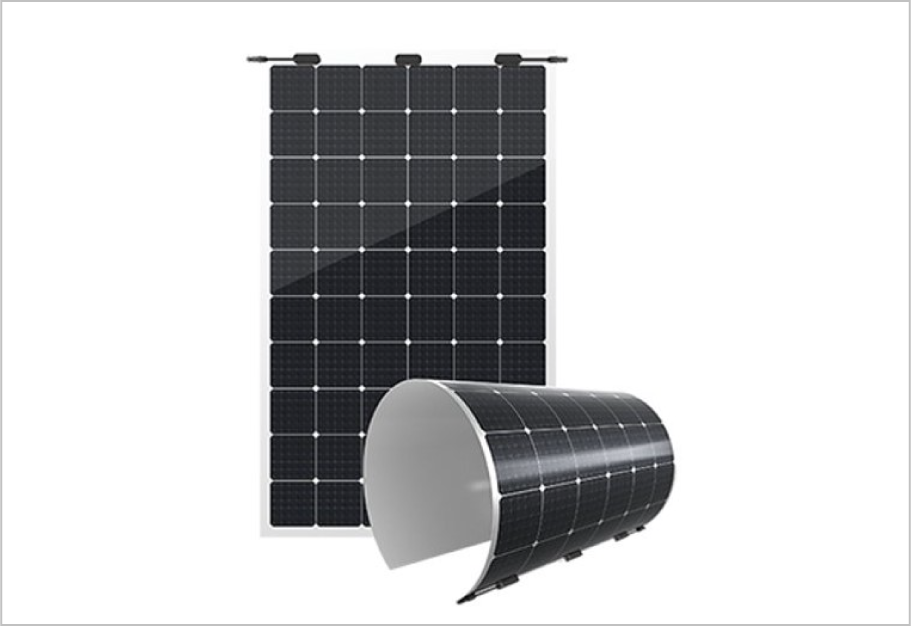

Photovoltaic modules

In February 2017, we opened a solar module factory in Izumi City, Kagoshima Prefecture, Japan. Our unique technological development capabilities, coupled with thorough automation of the production process, have enabled us to successfully mass-produce modules while also maintaining a high level of quality for each individual module. We only deliver products that have passed rigorous inspections at every stage of the production process, including various reliability tests and actual visual inspections.

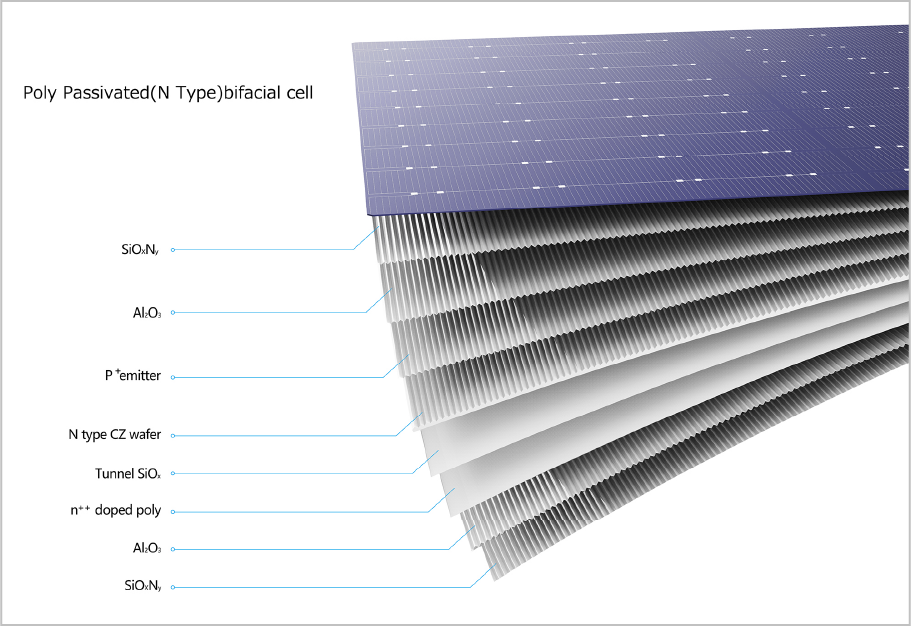

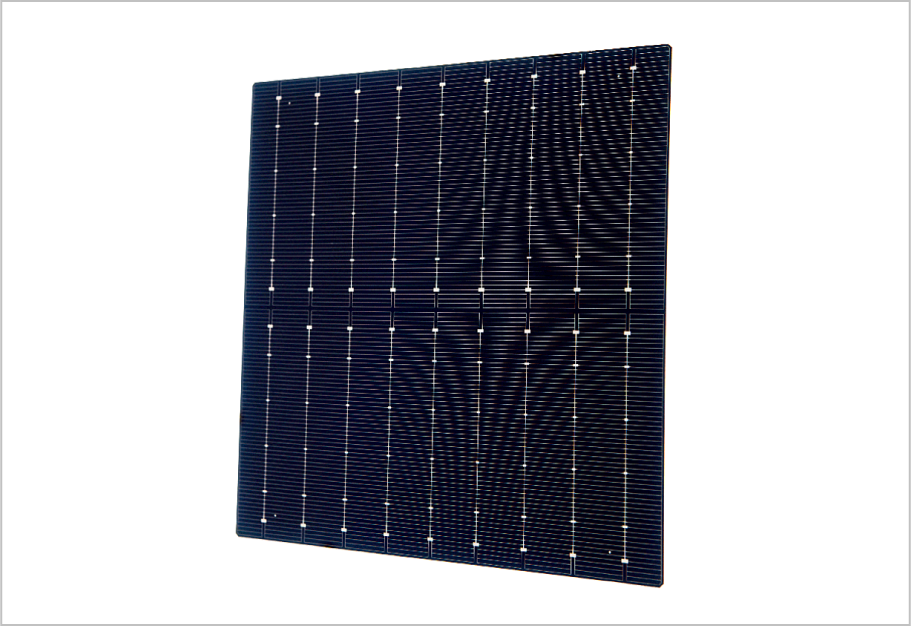

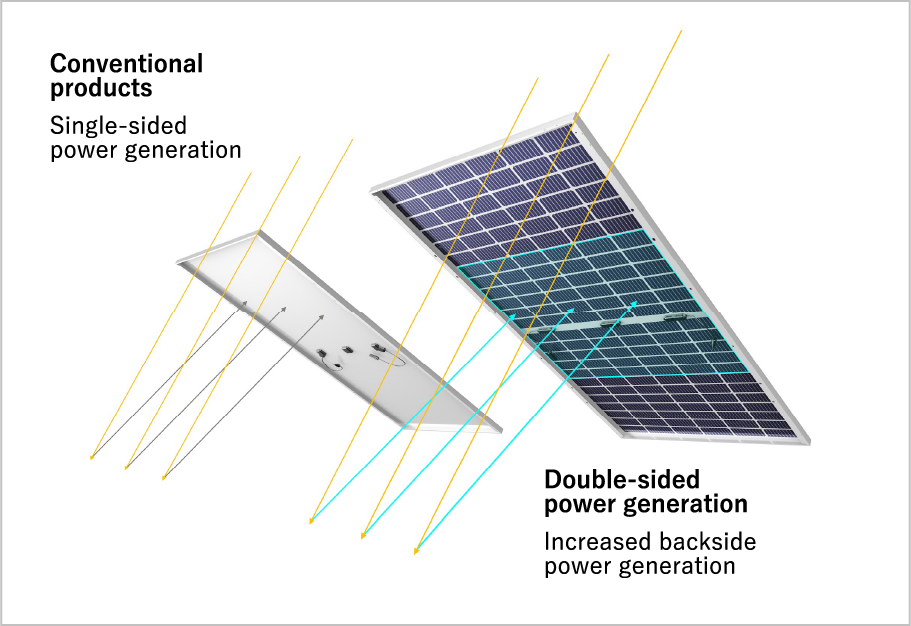

Energy Gap's solar cells are not only traditional P-type silicon (semiconductors in which charge is transferred via holes), but also N-type solar cells, which use N-type silicon (semiconductors in which charge is transferred via free electrons) to achieve high conversion efficiency. N-type solar cells do not suffer from light-induced degradation (LID) and can therefore maintain their power generation capacity for a long period of time.

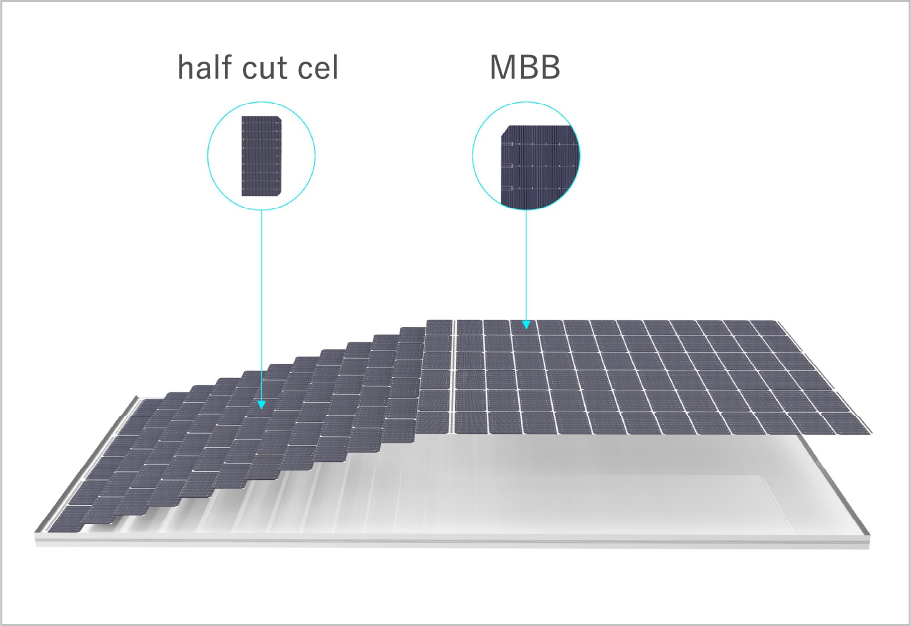

Halving the cells halves the internal current and lowers resistance, which also reduces power loss. Reducing power loss with half-cut cells results in a higher fill factor, a measure of cell quality. Modules with a higher fill factor offer higher cell conversion efficiency, leading to higher power generation performance.

Demand for installation on roofs and other locations where photovoltaic systems could not be installed due to weight restrictions is increasing. The need for photovoltaic modules with features such as lightness, thinness and bendability, which are not subject to installation location restrictions, is expected to increase steadily. As the weight load on the installation site and the construction burden can be reduced, the modules can now be installed in locations that were previously inaccessible. Also, the modules can be used as an emergency power sources in the event of disasters such as earthquakes. As such, they are expected to be installed and expanded to public facilities located in front of railway stations, such as bus stops and taxi stands, by municipalities and others.

speedy installation due to gluing method.

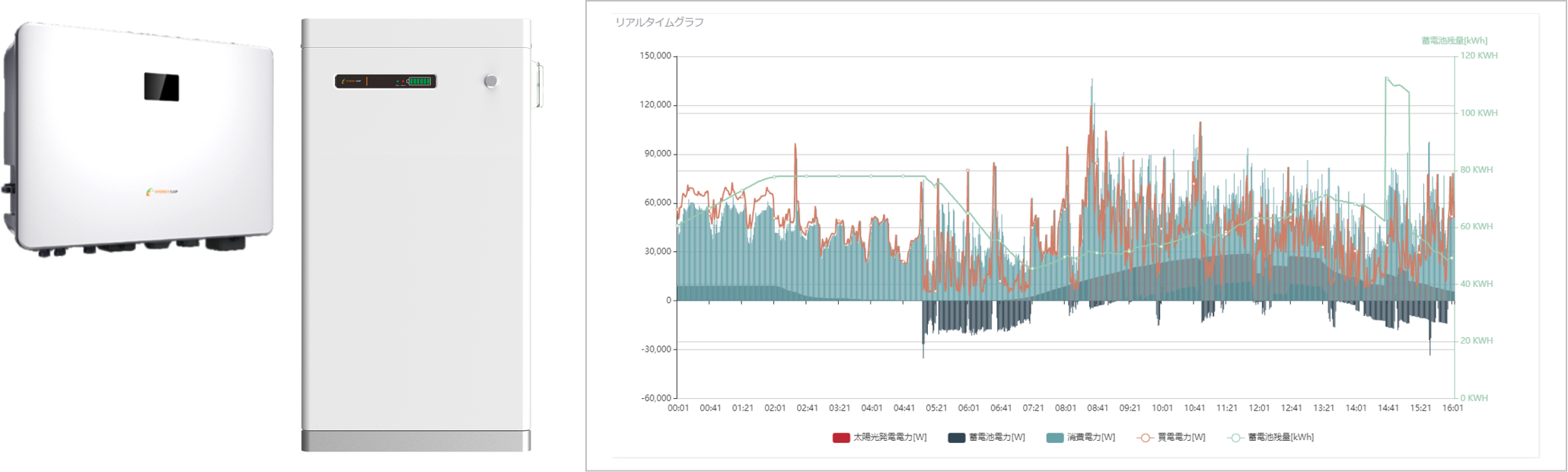

Lithium-ion energy storage systems

Energy Gap's hybrid battery storage system is a state-of-the-art LiB (lithium-ion battery) with a wide range of applications, from general residential to industrial use. Using world-class cells, the production of the battery units is fully automated. All product configurations are designed as all-in-one units to achieve high quality and advanced safety performance. By making effective use of hybrid battery storage systems, renewable energy generated at the customer's facilities can be used directly and to the maximum extent possible during normal times, while simultaneously reducing electricity costs. The system enables customers to reduce their CO2 emissions and increase their environmental and corporate value through the consumption of renewable energy electricity at home or in their businesses. In the event of a disaster, power failure or other emergency, the system can be used as an emergency power source to protect your family from danger, or as a BCP measure for your company.

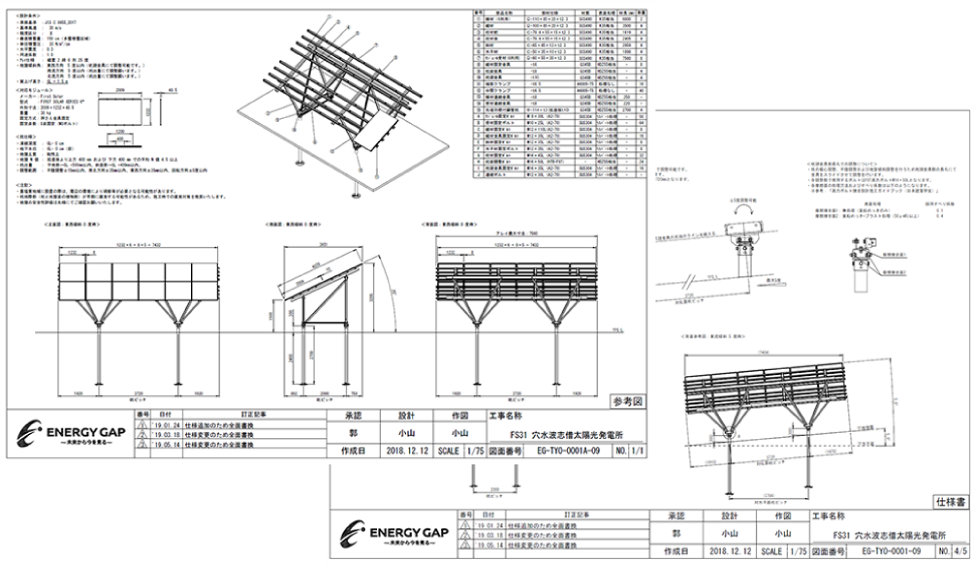

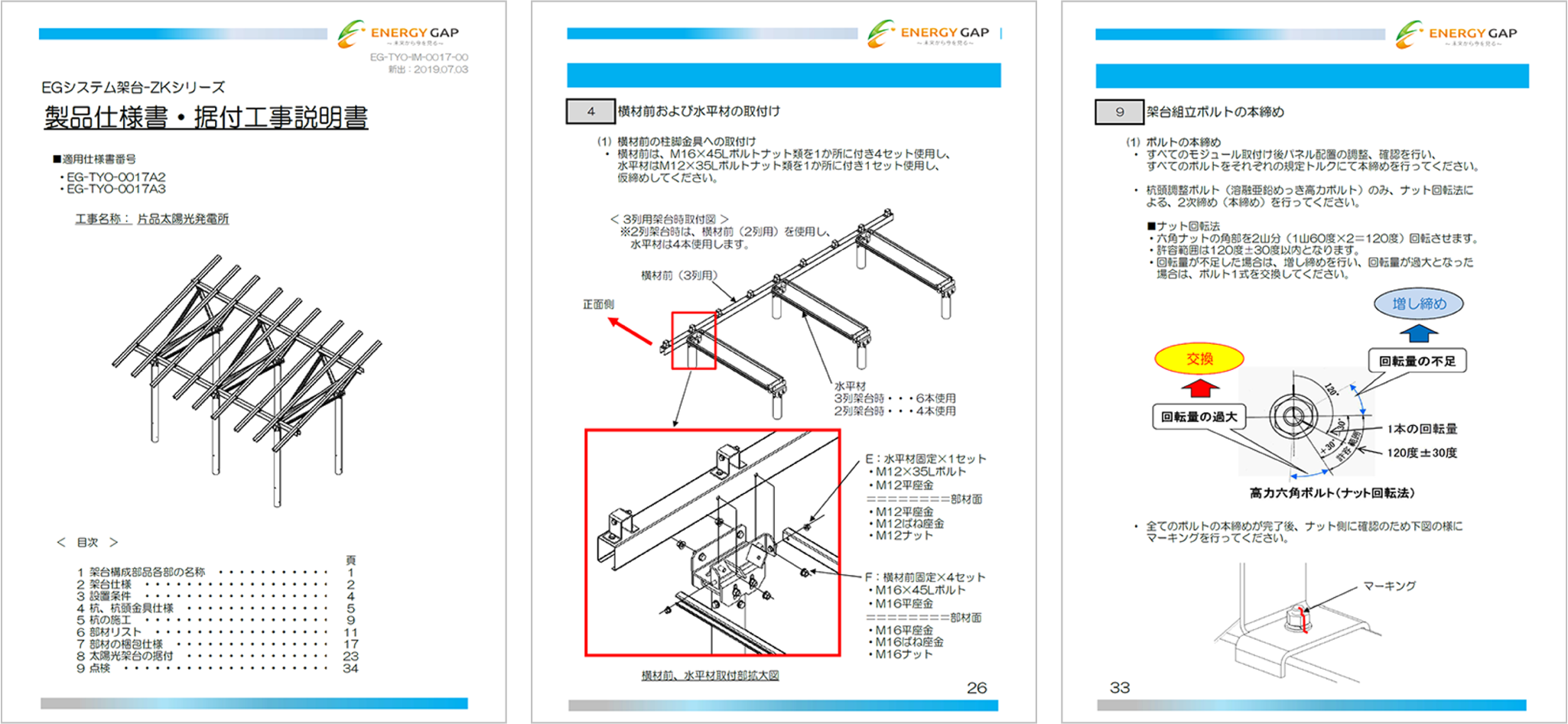

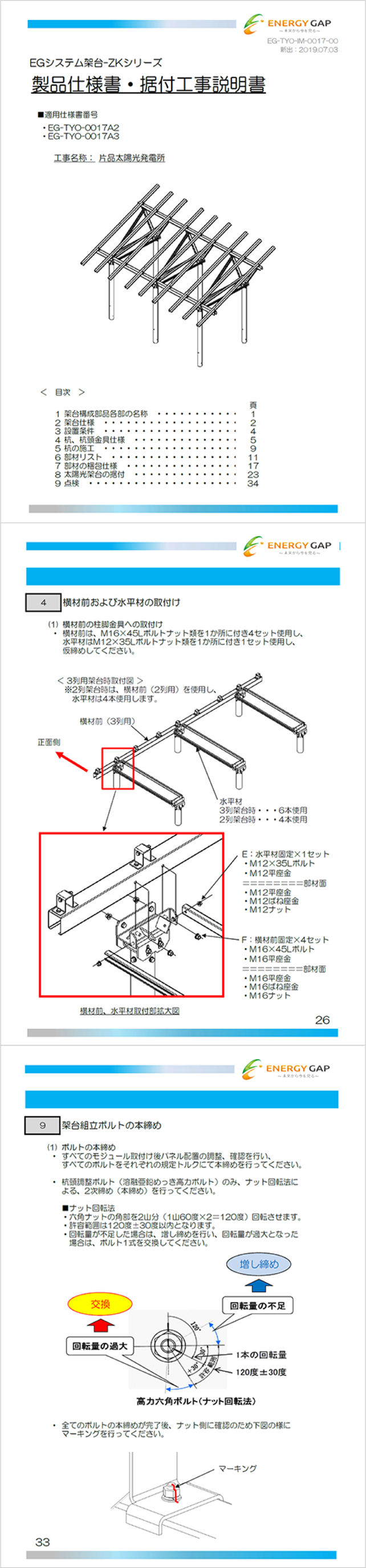

Photovoltaic system mountings

Energy Gap's racks provide total support for everything from small-scale to mega-solar systems. We undertake the entire process, from product development and design to production and supply, and handle filings with the Ministry of Economy, Trade and Industry. We provide flexible support for a variety of applications and needs, and offer commercial products with excellent workability and superior price-performance ratio.

In order to achieve high cost performance while complying with the technical standards of the relevant laws and regulations, our engineers provide customised design of components and structures that take into account the conditions of the power plant and ease of construction. We also assist in the preparation of support structure drawings and strength calculations, and can respond to any points raised by the Industrial Safety and Health Inspection Department.

New ideas for each project are analysed using stress analysis software. Based on the analysis results, we determine the strength of the components and structure. We carry out actual load tests using prototypes and design sturdy and safe mounting platforms that can withstand wind and snow.

In addition to product design, we also support on-site demonstration tests and mock-ups. We prepare product manuals and provide extensive on-site support.

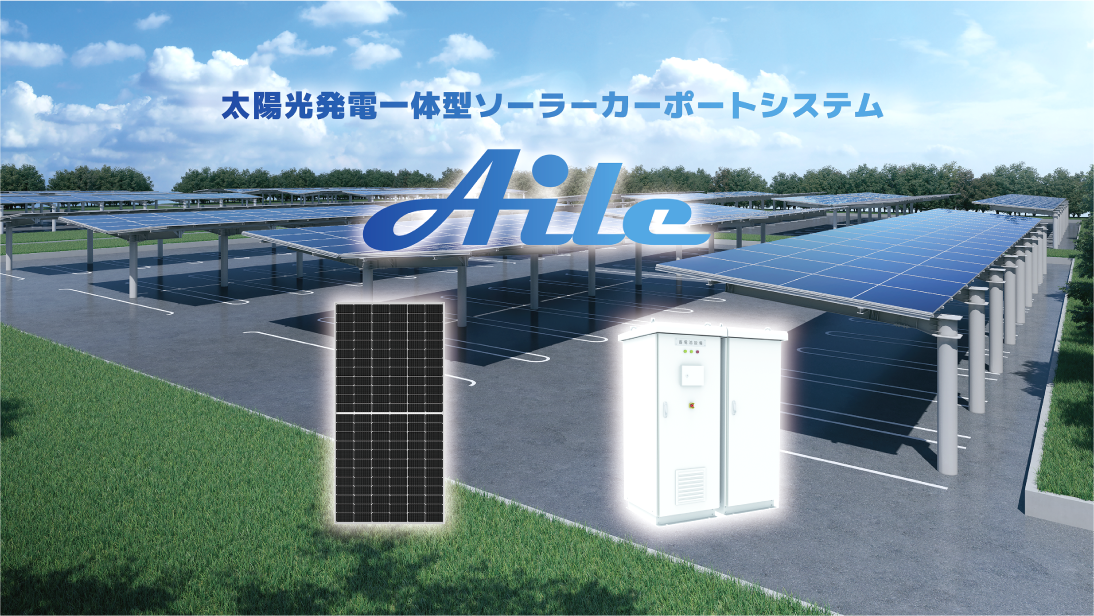

System solution products

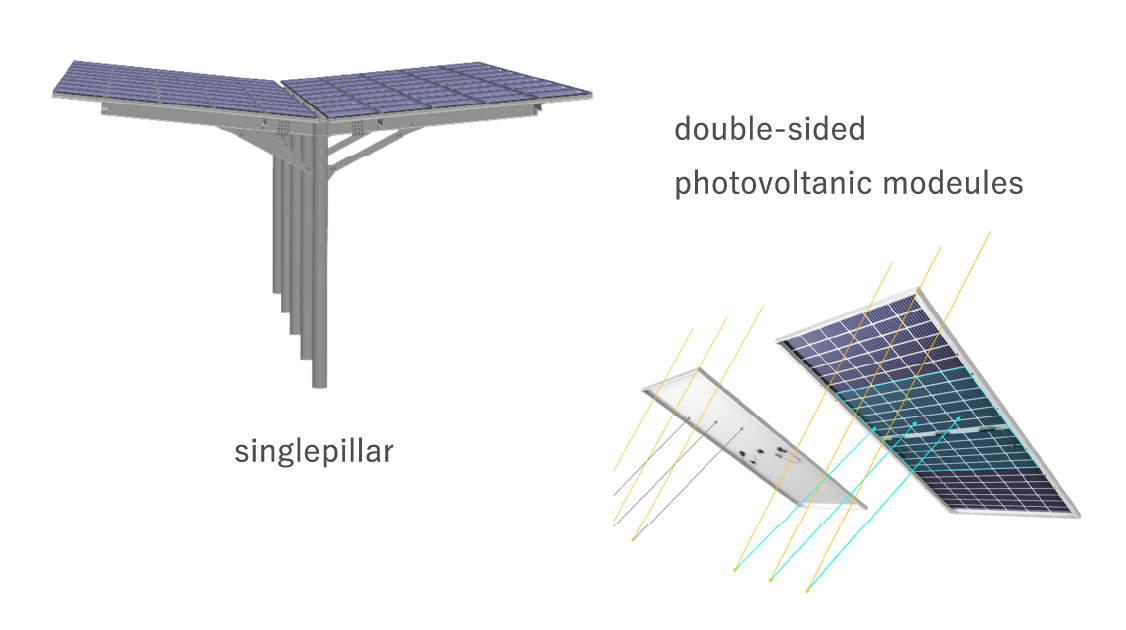

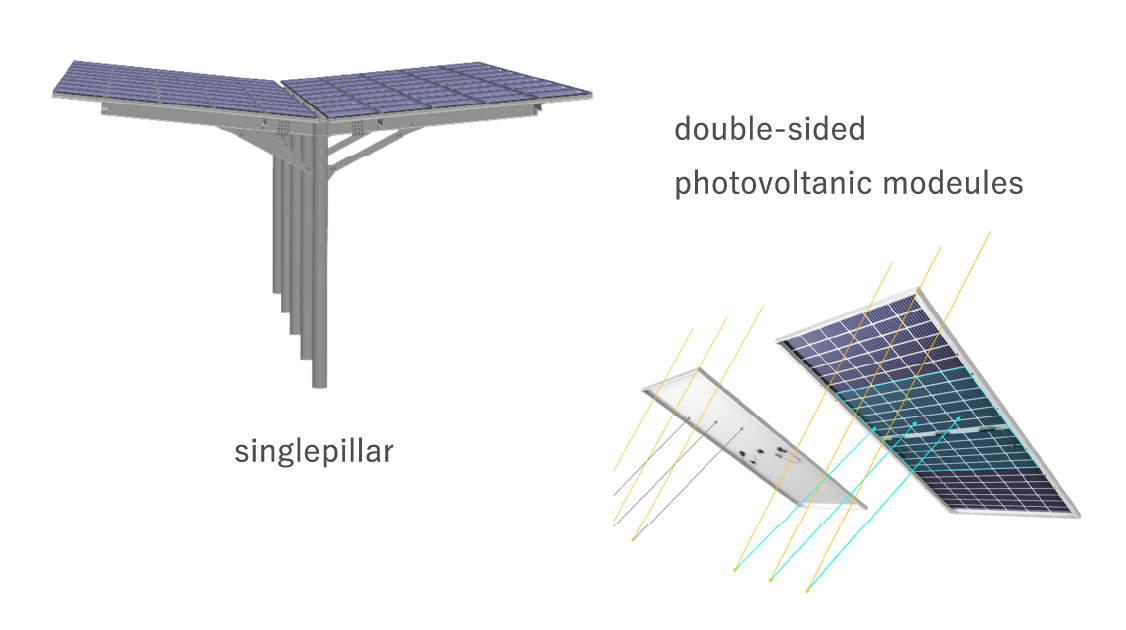

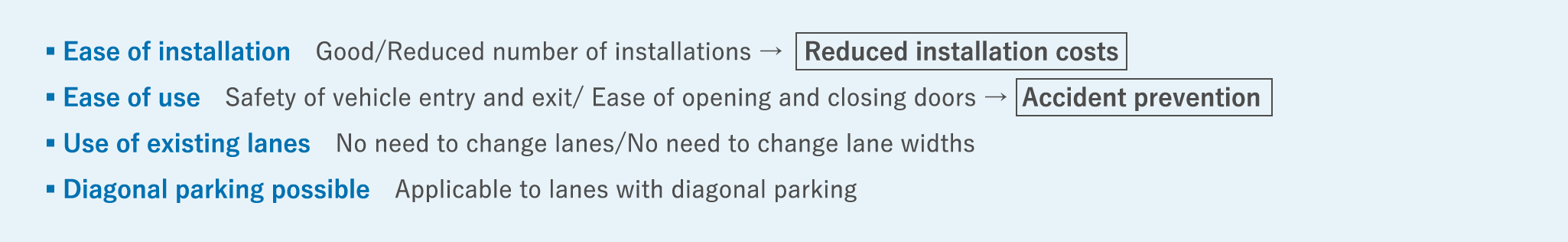

"Aile" means "wing" in French. The Aile Series is so named because of its single-footed design with integrated photovoltaic power generation, which looks like a wing. The Aile Series is designed to comply with the Building Standards Law even though it is fitted with double-sided photovoltaic modules, making it suitable for building permit applications.

( Mounting systems/modules/battery storage)

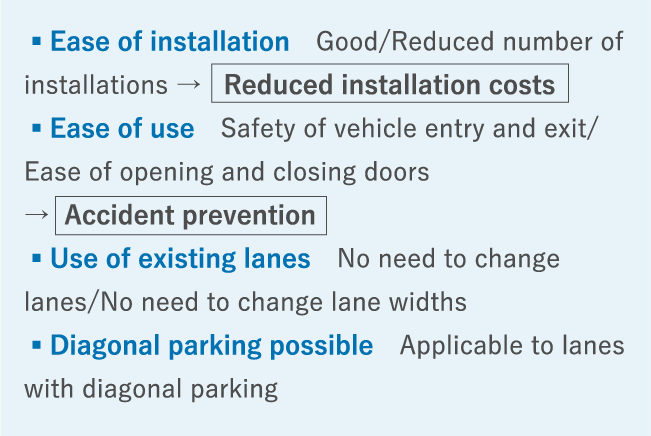

The post and beam assembly is no different from a standard carport. The procedure is the same: erect the posts, attach the brackets and assemble the beams. Whilst we have perfected the simple beauty of the product, we have also greatly improved its functionality and ease of installation.

By using the solar cell module as the structural material of the roof itself, we have created a new concept of a core-less carport.

In recent years, demand for electric vehicles has increased rapidly as environmental regulations have progressed, particularly in the USA and Europe, to combat global warming. Japan also aims to achieve carbon neutrality by 2050, and has set a target of 50% penetration of electric vehicles including hybrid vehicles (PHV) and fuel cell vehicles (FCV) by 2030 as part of the 'ZEV Promotion Programme'. Solar carports with EV outlets, battery storage and quick chargers allow EVs and other electric vehicles to be recharged while they are parked.